How To Repair Fishing Rod Eyelets

While looking down a fishing rod, you will discover all the guides spaced out from the handle up to the tip-top. Leading the line down the rod and out of the tip-superlative, guides are one of the well-nigh essential components of a fishing rod then knowing how to replace 1 that breaks is a huge benefit.

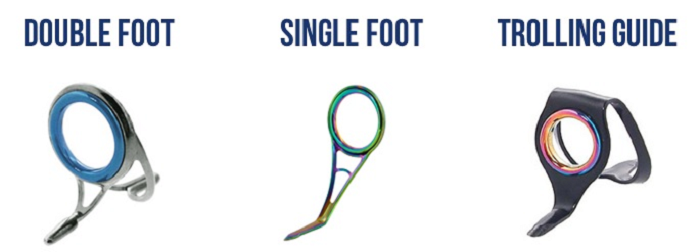

Each of these guides is every bit—if not more—important than the last. Whether it'south a double human foot, unmarried foot, or trolling guide, all are as valuable to the overall performance of the fishing rod and without 1 guide, the remaining rod'due south performance is severely reduced. Removing and replacing broken guides is not only possible, but when done with the correct technique, it is as well rather uncomplicated.

Using the post-obit steps, y'all can successfully remove and replace any broken guide on your fishing rod.

Measuring Rod Guides

Ordering a new guide is easy as long as y'all have the design and measurements needed to find the right replacement.

Ordering the replacement guide starts by choosing the pattern, then finding its measurements.

Guides are measured in millimeters and determined co-ordinate to the exterior diameter (OD) of the insert ring, or in cases where the casualty is the insert ring, the within bore (ID) of the guide frame tin exist used as a substitute since both translate to the aforementioned measurement.

Removing Rod Guides

A common rod failure in fishing, damaged guides are oft the effect of being used as a hook keeper, stepped on, or bashed confronting a hard surface. In some cases, the guide frame will remain intact, but the insert ring will end upwards cracked, chipped, or missing. Never go on line-fishing with an impaired insert ring considering it will shred your fishing line and eventually, sever the line completely.

Regardless, each scenario will crave a replacement guide and the process begins by first removing that damaged guide. Fix your piece of work station for removing this guide past setting aside a razor blade, a modest flame, a pair of pliers, and a china marker.

one. Utilize Gentle Heat

Start, using a minor flame, such equally a lighter, candle, or alcohol burner, quickly even so carefully whisk the flame back and forth over the epoxy on top of the damaged guide'southward foot. This gentle heat will loosen up the epoxy'south bond allowing the razor blade to cutting through the layer of end similar butter.

2. Cut Through Terminate

Once the bond has been weakened by the gentle heat, take a razor blade and cut through the cease directly on tiptop of the guide foot.

Heating the epoxy will allow you lot to cut through the guide wrap easily without damaging the blank.

Since the bulk of rod blank materials can be hands damaged by a razor blade and the combination of thread and epoxy is simply millimeters thick, cautiously cutting directly over the guide foot will help avert tarnishing the rod blank itself.

3. Remove The Damaged Guide

Side by side, the guide should just autumn off later the razor blade severs the cease over the guide foot, only if the guide remains, accept the pliers and pull that broken guide straight off the blank. It is important to pull the guide directly up and abroad from the bare rather than at an angle, which could cause the sharp guide foot to drag over the rod blank.

4. Clear Any Backlog

Now that the guide is removed, there may be some leftover epoxy and thread in the guide's previous location. To remove the residual cloth, utilize your fingers or pliers to peel the stop back then off of the rod blank. Be certain to remove the largest chunks of finish because they will complicate the installation of the replacement guide.

v. Make Your Mark

Finally, with the broken guide and leftover finish removed, use the china marker to put a dash where the replacement guide will adhere. Typically, the previous guide volition leave a pes print making it easy to line up the new guide nonetheless, that might not always exist the case and so make a mark with your china marker just to be safe.

Installing Replacement Rod Guides

Sure fishing with a rod when it'due south missing a guide won't kill y'all, it certainly isn't recommended. Because how many line complications are possible in the space betwixt the remaining guides, avoid cut whatever corners to get back out on the water and return but when you accept a stock-still angling rod you can cast with confidence.

Guides are essential to the fishing rod, avoid fishing with a rod before the guide is replaced.

With that said, the process for replacing a missing guide is straightforward and relatively quick. Start past gathering the tools, you lot volition need the following: a small file, some lite sand paper, a fresh razor blade, a spool of thread, a two-part epoxy mixture, a rod dryer, and a burnishing tool. At present with these nearby, you are ready to begin replacing the guide.

1. Guide Preparation

Prepping your new guide is a must earlier information technology comes to time to attach it permanently. Properly prepping the new guide past grinding downwardly the guide human foot with a small file is important to the wrapping process. Take the fourth dimension to file down the guide foot to a point earlier attaching it to the blank. This ensures a smooth transition one time you commencement wrapping thread from the blank upwards onto the guide foot.

A guide file helps to grind downward any burrs or uneven edges on the guide foot.

Once the point is complete, run the bottom of the guide pes over your finger nail. Finger nails mimic the surface of a rod blank so this test will determine if the bottom needs to be sanded. If it scratches your nail, it volition scratch your rod bare. A simple set up, just have some low-cal sand paper and vitrify out any burrs or points created underneath the guide foot.

A pocket-sized task to save a major headache, filing down the guide foot and sanding downwards the lesser of the human foot will help you wrap the guide securely while fugitive any scratches your rod bare.

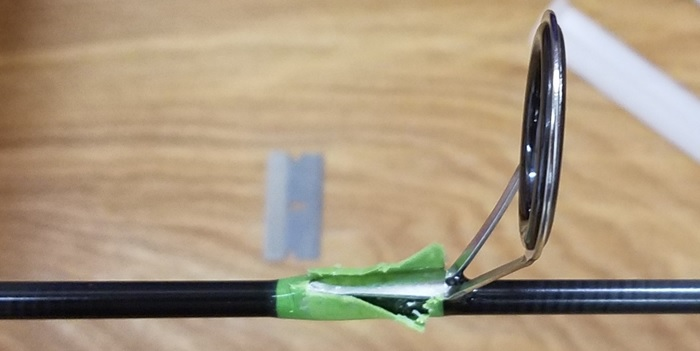

2. Double Bank check Guide Alignment and Spacing

Since the new guide has been prepped to avoid damaging the blank, identify it on the mark or in the foot print of the previous guide. Then, apply a few rotations of masking tape to hold it in place. This makeshift attachment allows you to double check your guide alignment and spacing.

Whether heart-balling these guide tests or using the always authentic CRB Spine Finder and Deflection System, what is most important is that yous double check the guide alignment and spacing before permanently attaching the replacement guide. Once you are satisfied with the replacement guide'southward alignment and spacing, move forward to the wrapping process.

iii. Wrap Your Guide

Step 1

Start about i/4 inch from the guide, begin wrapping from left to right. Showtime the thread wrap by wrapping effectually the rod blank a single time. Next carefully place your finger on the blank where the ii threads meet and slowly rotate the rod while simultaneously crossing the running thread over the tag end.

Essentially, yous are cross-stitching an X blueprint, which will in turn lock the thread in identify.

Step 2

Execute roughly eight wraps so stop and trim the remaining length of the tag stop off as shut to the wrap as possible. Go on wrapping, only keep monitoring each wrap so that they are tightly seated adjacent to the previous wrap.

To aid keep the wraps tight, utilise the burnishing tool to set up any mistakes and cut down any extra space between wraps.

Stride 3

Be careful while wrapping the transition from rod blank upwardly onto the guide foot. This is a common place to make the mistake of assuasive the threads to sit on top of each other rather than tightly side by side to each other.

Pace 4

When you go well-nigh 1/8 inch from the terminate of your wrap, take a modest slice of thread and fold it over into a simple loop. And then, slide the loop under the running thread—the loop should go in the same direction you are wrapping—making sure it's tight and secure to your wrap. Continue wrapping over the loop, most eight to 10 more times.

Step v

At this betoken, place i finger on the superlative of the wrap and utilize your free hand to cut the running thread from the spool. And then just grab the tag end yous but created and skid information technology through the loop.

Step 6

Gently pull the loop back through the wraps until both the loop and the tag cease of your thread emerge from nether the wraps.

Step vii

One time the loop and tag end emerge, lay the razor blade flat against your wraps with the blade facing where the tag finish comes out from nether your wraps. Take the tag finish and pull it over the razor bract, cutting the tag end flush to your wraps.

Laying the razor apartment against the wrap allows you to cut the tag finish affluent with the wrap.

Never use the razor blade similar a saw because the back and forth motion volition fray the thread potentially damaging the strength of the wrap.

Steps 1 through vii will wrap a single foot guide, but simply repeat the process if you are wrapping a guide with a double foot.

Footstep 8

Make sure you have your rod guides lined upward perfectly. The eye test is actually the best way to exercise this. Just hold your rod upward to eye level and look down the rod blank to brand sure the centers of each guide match up.

4. Use Epoxy Finish

Now that the guide is wrapped and y'all are satisfied with how it looks, it'due south fourth dimension to lay the epoxy end over the guide wrap. We propose a two-office epoxy with a resin and a hardener that mix together to give your finished rod a clean, sleek profile.

Make sure to keep the brush steady on the ends of the guide wrap in lodge to create a shine, direct edge.

Applying a thorough layer of epoxy ensures a strong bond that holds the guide wrap in identify.

With the epoxy cease on the new guide wrap, identify your angling rod in a rod dryer and leave information technology rotating for the suggested curing time.

5. Return to Angling

Later the curing procedure is over, the fishing fun can over again brainstorm. Render to the water with peace of mind knowing that you replaced the broken guide and that you tin can continue casting with confidence.

Call back, breaking a guide off your rod is not the finish and rather, use this communication to go back on the water with a fishing rod you know yous can trust for that next big catch because you stock-still it yourself!

Cheque out our rod guide selection hither…

Source: https://blog.mudhole.com/how-to-remove-replace-rod-guides/

0 Response to "How To Repair Fishing Rod Eyelets"

Post a Comment